Product Lines and Services

Microbes

Microbes or bacteria are single cell life forms – each individual cell is a separate, unique organism. Bacteria often grow into colonies that appear as jelly-like masses, but each cell remains an independent, individual life. Bacteria reproduce by a process called cell division. Mature bacteria reproduce by dividing into two daughter cells, each identical to each other and the parent bacteria. Under ideal conditions, bacteria can reproduce very rapidly, producing a new generation every 20 to 30 minutes.

Microbes fall into very large groups that have very diverse functions and classifications. We select and culture only those strains that are non-pathogenic, are superior for their waste digestion capabilities and are able to generate large volumes of enzymes. For each of our microbial products we select the best microbe strains for each application and blend them together with micro and macronutrients to make superior concentrates and ready-to-use treatment products for a variety of waste treatment applications.

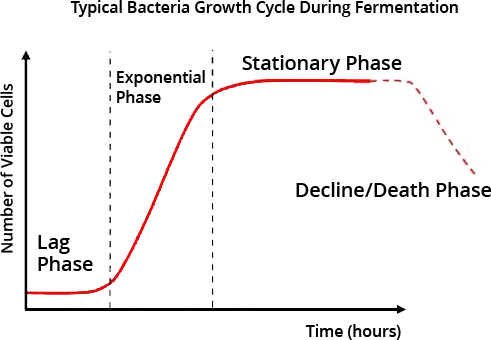

Bacillus Licheniformis Fermentation Process (Time Elapsed = 25 Hours)

Certain bacteria species have several identifiable characteristics that make them superior for waste treatment applications. Some of the microbe species cultured and utilized in our proprietary product formulations include:

Bacillus Amyloliquefaciens • Bacillus Licheniformis • Bacillus Subtilis • Bacillus Megaterium • Bacillus Pumilus • Paenibacillus Polymyxa • Lactobacillus Acidophilus • Others

Enzymes

Enzymes are not living organisms. They are simply biological catalysts. Unlike bacteria, they cannot grow or reproduce. Living microorganisms, or bacteria, are the “factories” that produce enzymes. There are essentially five factors that can affect enzyme activity – enzyme concentration, concentration of the substrate, effects of inhibitors or activators, pH and temperature, with the most important factor being the contact time between the enzyme and the substrate.

Enzymes are specific, so that one type of enzyme can work on only one type of molecule. Therefore, a protease enzyme will only break down complex proteins into simple pieces, but will have no effect on fats, oils, or greases (FOG). Through technological advancements in the fermentation of microorganisms, application specific enzymes can be produced in very high quantities. Because enzymes are present in all biological systems they are one piece of our sustainable technologies as they can be readily absorbed back into the environment.

Septic Systems & Grease Traps

The purpose of any wastewater treatment system whether it is a municipal treatment plant or an onsite septic system or grease trap system is to protect the ground and surface waters by reducing the amount of organics, nutrients, and pathogens discharged into the environment. All on-site or decentralized wastewater treatment systems, typically referred to as septic tanks, grease traps, or cesspools, use microbes for bacterial digestion to remove organic waste from the wastewater. Because microbes do the heavy lifting in residential or commercial on-site or subsurface systems, selective microbe species are particularly important.

Our biological septic system, cesspool, and grease trap products are cultured, grown and formulated from naturally occurring microbe species found in our environment. These selective strains are chosen for their superior ability to grow prolifically, digest organic waste in on-site treatment systems without producing foul odors and are non-pathogenic to the environment. When we treat these less than perfect septic tank, grease trap or cesspool systems, our superior bacteria strains work in harmony with the wastewater to live and reproduce there continuously digesting more and more waste as it enters the system.

Aquaculture & Aquatic

Aquaculture in much of the world is stricken by disease such as Vibrio and other viruses. Microbial ecology, via addition of “beneficial microorganisms”, is the best solution to achieving high survival rates and keeping fish and shrimp species healthy during their lifecycle. Beneficial microorganisms in aquaculture help control biological oxygen demand (BOD), pathogens, odors, bottom sludge and water quality.

Studies also show that Aquaculture production must double within the next 15 years in order to keep pace with demands for food resulting from population growth. In order to sustain the healthy production of shrimp and fish going into the future, we must embrace an eco-friendly approach towards microbial ecology in worldwide aquaculture production.

In aquatic environments such as ponds, lakes and lagoons a decrease in water clarity can significantly reduce water quality and oxygen levels. Using our natural, non-chemical methods via bio-augmentation and other technologies we can reduce high organic loading improving the water quality and the aquatic environment.

Microbiology

Microbiology is the study of a hidden world of microscopic organisms that include bacteria and fungi. We study and research groups of selective microorganisms and their enzymatic properties to determine what species are superior for applications in the industries we serve and to help shape and influence a sustainable environment for the future.

Our microbiologists play a key role not only the study and selection of specific microscopic organisms for our product lines and applications, but also in fermentation, production, quality control and research and development. Research in the fields of microbiology and bacteriology continue to unlock a vast catalog of undiscovered microorganisms that can help clean up pollution and solid wastes, improve manufacturing processes, enhance farm crops, and improve efficiencies in wastewater treatment processes.

Custom Solutions

REX-BAC-T® Technologies offers custom formulations, custom manufacturing and custom packaging. To provide added value to our customers our technical staff can work with you to develop custom formulations for nearly any application. If you already have existing products, we can match, improve, or reformulate these products to meet your needs or your customers’ requirements.

Choosing the right packaging or labeling is critical to your business. Our graphic designers are able to customize labeling for you using your logos, content and information. We can package your products in bottles, jars, gallon containers, pails, drums, bulk totes or super sacks. If you require water-soluble film (PVA) for your granular or powered products we can customize packaging sizes based on your application requirements or customer specification.

If you are looking for someone to partner with for your custom formulations, custom labeling, custom packaging and turnkey solutions please contact us to better understand your business, product line(s), target market and objectives. Our expert team will work with you and your companies needs from concept to completion.

Engineering

Our engineering staff has decades of experience providing innovative and cost-effective solutions using proven and emerging technologies to solve our customers’ daily challenges. This diverse group of customers has come to rely upon our breadth of expertise and our interdisciplinary solutions for treating water and wastewater in the residential, commercial, industrial, municipal aquatic, agricultural and government sectors. This unique combination of expertise in the biosciences, microbiology and engineering allow us provide unparalleled support to bring you or your business the best solution for your application or process.

Wastewater Treatment

Effective and sustainable water and wastewater treatment are crucial for our expanding urban populations. Wastewater processes and their complexities are ever increasing throughout our cities and communities. Municipalities face increasing challenges due to older, outdated facilities which exceed their designed capacity. In addition, commercial and industrial wastewater treatment plants face ever increasing regulatory constraints and discharge limitations. These can be defined as combating solids, sludge, malodors, organic buildup, and grease resulting in undesirable levels of BOD, COD, H2S, TSS, FOG, and poor DO stability.

These industries and operators are tasked with finding and improving operational efficiencies and we can help. Using one or several of our wastewater treatment technologies we can positively impact these processes and improve the overall wastewater quality.

Odor Control

Most areas where wastewater or solid materials are collected, stored or treated have the potential to generate and release nuisance odor to the surrounding area s as a result of an anaerobic or "septic" condition(s). Sulfur reducing bacteria (microbes) generate hydrogen sulfide (H2S) when oxygen is not present. These microbes survive by gaining energy at the molecular level by borrowing or sharing electrons causing the sulfides to be produced. Common food sources are sugars, fats, and volatile fatty acids containing sulfur and nitrogen. Due to low solubility in water, the resultant rotten egg odor escapes to the surrounding areas causing foul odors, corrosion and potential health hazards.

Bio-augmentation using selective non-sulfur reducing species of microbes mitigates the production of these sulfides. Utilizing one or multiple technologies we provide the right products and ecological solutions to handle the unique characteristics of your given application.

Liquid and Vapor Phase Carbon Filtration

With our carbon adsorption systems the contaminated air stream is passed over a bed of activated or impregnated carbon. The odor causing contaminants, such as hydrogen sulfide, are adsorbed removing the malodors associated with the processes. Our capabilities include both gas phase and liquid phase technologies. These systems are used widely throughout wastewater systems, lift stations, wet wells, sewer vent pipes, septic tank and grease trap systems, and other industries where point source odors are a nuisance. These technologies are a primary consideration as manufacturing, collection and treatment systems are encroaching closer to urban areas.

If you need custom odor control solutions or carbon adsorption equipment, please contact us and one of our engineers will work with you to provide the best available technologies to solve your odor control problems.

Other Industries

REX-BAC-T® Technologies works to deliver high quality products, solutions, engineering and technical to a broad mix of customers in the private, public, government, and consumer markets. Our core products and services are firmly focused industrial biotechnology, biomass, and wastewater treatment technologies. Building from our foundation we are able to offer our customers turnkey products, equipment, and engineered solutions that complement our core product lines. These synergistic product lines include liquid and gas phase carbon filtration, aeration systems, effluent filtration, programmable metering systems and many others so that we can serve our customers needs from top to bottom.